Description

70-40 Zinc Paste Metaflux

- MATTE FINISH: cold galvanization

- Color: matte gray

- Dry sheet zinc: 96% (+/- 1%)

- Zinc purity: 98.5 – 99%

- Temperature resistance: up to +800°C [+1,472°F]

FEATURES:

- Made of 99% pure zinc ensuring lasting protection.

- Approximately 96% pure zinc in the dry sheet.

- Highly resistant to corrosion, abrasion, and impact.

- Resistant to salt, saline water, acid rain, and heat.

- Applies like paint and can be applied in a thick layer over a large surface.

- No zinc settling in the pot; easy and homogeneous mixing.

- Temperature resistance up to 800°C.

- Metaflux’s Zinc Paste is distilled to eliminate lead.

- Waterproof, adhesive, and highly resistant.

- Recommended and used for long-term protection in military and civilian installations, even in the most extreme climates in the UK.

- Contains very little solvent.

- Flash point 23°C.

- Specific gravity 2.85 g/ml.

- Oxidizing drying, without capillary cracking.

- Weather-resistant.

- Offers dual protection to steel, acting as both a barrier and galvanic protection.

70-40 Zinc Paste Metaflux

SURFACE PREPARATION:

The choice of surface preparation and cleaning before application is as important, if not more important, than the coating itself.

Mix well: ideally with a mixer free of any greasy substances or other contaminants for 5 minutes * do not shake the product *

It’s essential that the surface is free of oil, dust, grease, or other contaminants.

Recommendations: Metaflux’s Zinc Paste can be painted; however, an adhesion test on a small part of the piece is recommended due to the multitude of paint brands available.

Can be applied on the previously cleaned old galvanization layer.

Sandblasting, if necessary, for structural components to remove rust and/or scale.

- Recommendation: If needed, apply a thin layer with a brush to fill cavities, bolts, plates, and edges.

- Acts as a protective barrier and repair on the used surface.

- In case of applying two coats (depending on thickness and humidity), we recommend an interval of 2 – 4 hours.

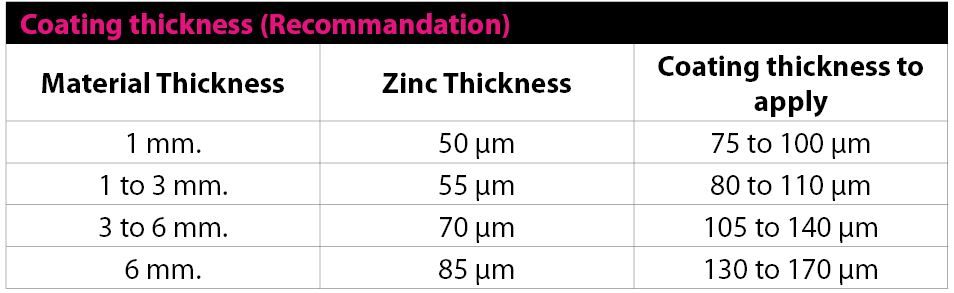

- Can also be applied in a thick layer up to 150μm.

- Surface humidity should not exceed 90%.

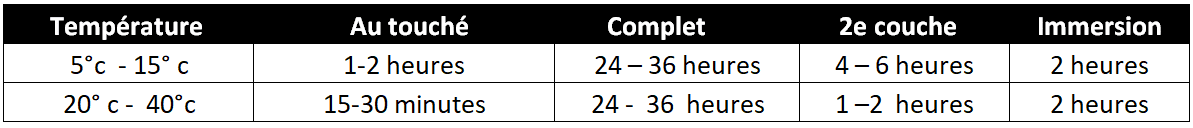

Attention: For informational purposes, atmospheric conditions can affect drying time.

For touch-ups and repairs, application is usually done with a brush and roller.

For spray application:

Recommended nozzle 0.38 mm = ^ 0.1482 / 0.43 mm = ^0.1677

Spray angle between 50°C and 60°C

Nozzle pressure at 2800 psi (200 kg/cm2)

Use solvent not exceeding 10%.

Viscosity 320 mPAS

USES: Metal manufacturing plants – Cooling towers – Stair ramps – Safety rails – Steel structures – Guardrails – Signage – Roads and Bridges – Maritime Industry – Petrochemical facilities – Aerospace – Water treatment plants – Construction – Antenna Towers and many more.

Immersion: 2 Hours

·Protect from heat exceeding 35°C, avoid direct sunlight.

Shelf life:

Open container: 1 year

Closed container: 3 years

70-40 Metaflux Zinc paste

70-4001 / 70-4002 / 70-4010 / 70-4050